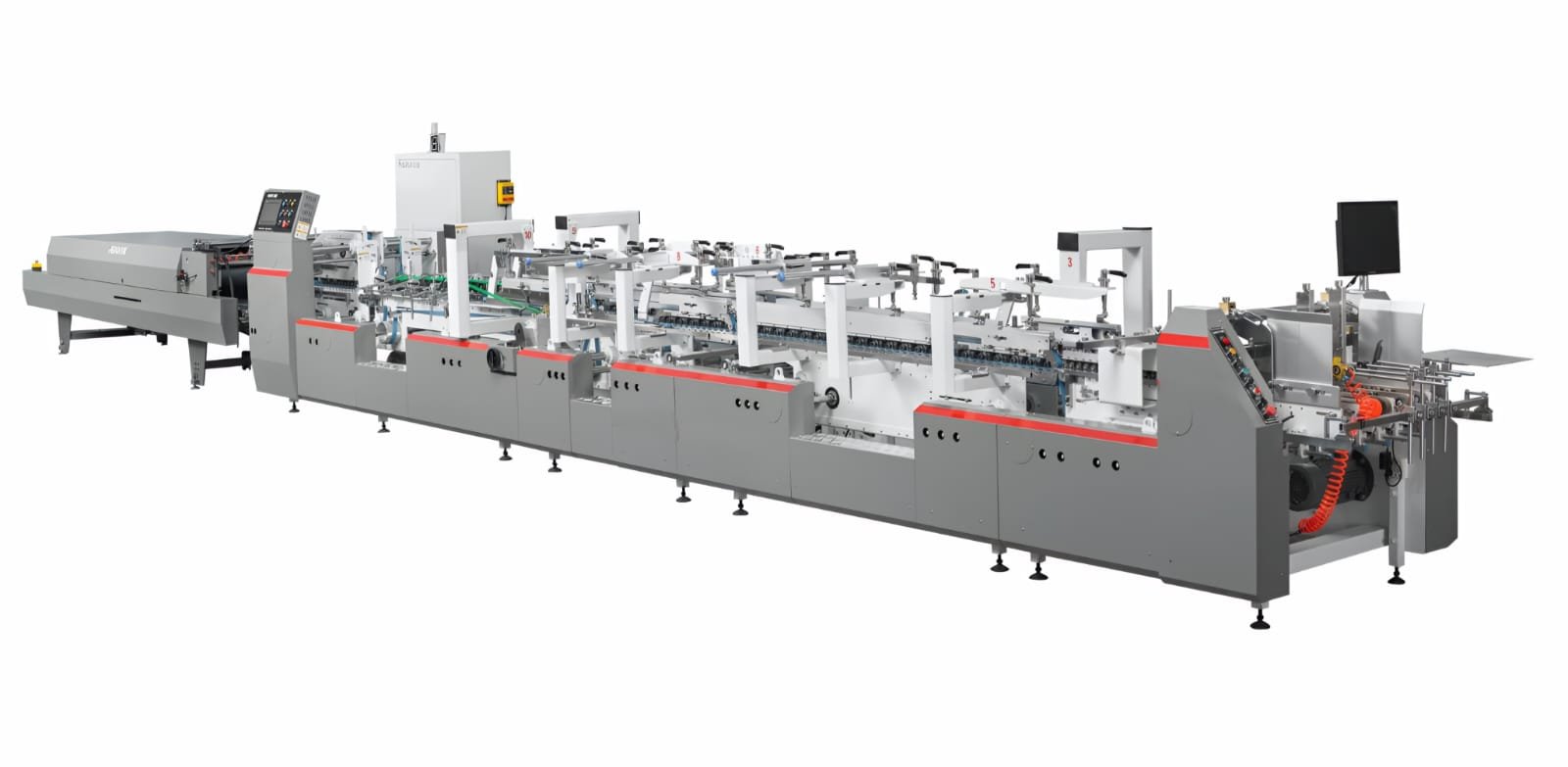

Automatic folder gluer machinet

1. Model – EnduraFold 700/900/1200.

This high-speed corrugated folder gluer is engineered for maximum productivity, precision, and operational reliability. Designed to run at speeds up to 500 m/min, the machine ensures efficient and consistent output while maintaining excellent carton quality. The advanced & suction feeder with an independent AC motor, pneumatic vibrator, and intelligent monitoring system enables smooth and accurate feeding of a wide range of corrugated cartons, including straight line and crash lock bottom types. A longer folding and closing section ensures stable carton forming while effectively minimizing fish-tailing issues.

The machine features dual-side gluing tanks with micro-metric adjustment for precise glue application, along with an easy-clean system that allows quick maintenance and minimal downtime. The flexible trombone and delivery sections are powered by independent AC motors and equipped with pneumatic pressure adjustment, clapping devices, and squaring systems to ensure perfect carton alignment and strong bonding, even at high speeds. A long delivery section with adjustable height, length, and pressure guarantees uniform pressing and accurate stacking of finished cartons.

The machine integrates PLC control with a 10-inch full-color touchscreen, allowing operators to monitor production status at a glance and make quick adjustments with ease. The overall layout supports fast job changes, improved efficiency, and higher output for both standard and complex carton designs. With flexible feeding widths and compatibility for multiple flute combinations, this machine is an ideal solution for manufacturers seeking high performance, reliability, and premium finishing quality in corrugated carton production

Model | 700FC/W | 900FC/W | 1200FC/W |

Carton board | 180-800 g/㎡ | 180-800 g/㎡ | 180-800 g/㎡ |

Corrugated board | N, F, E | N, E, F | N, E, F &B |

Max. Speed | 500m/min | ||

Inching Speed | 20m/min | ||

Blank width | 700mm | 870mm | 1180mm |

Min Size | 60 x 50mm | 60 x 50mm | 60 x 50mm |

Way of Pre-fold | First folding line 180 degree; and the third folding line 165 degree | ||

Related Products

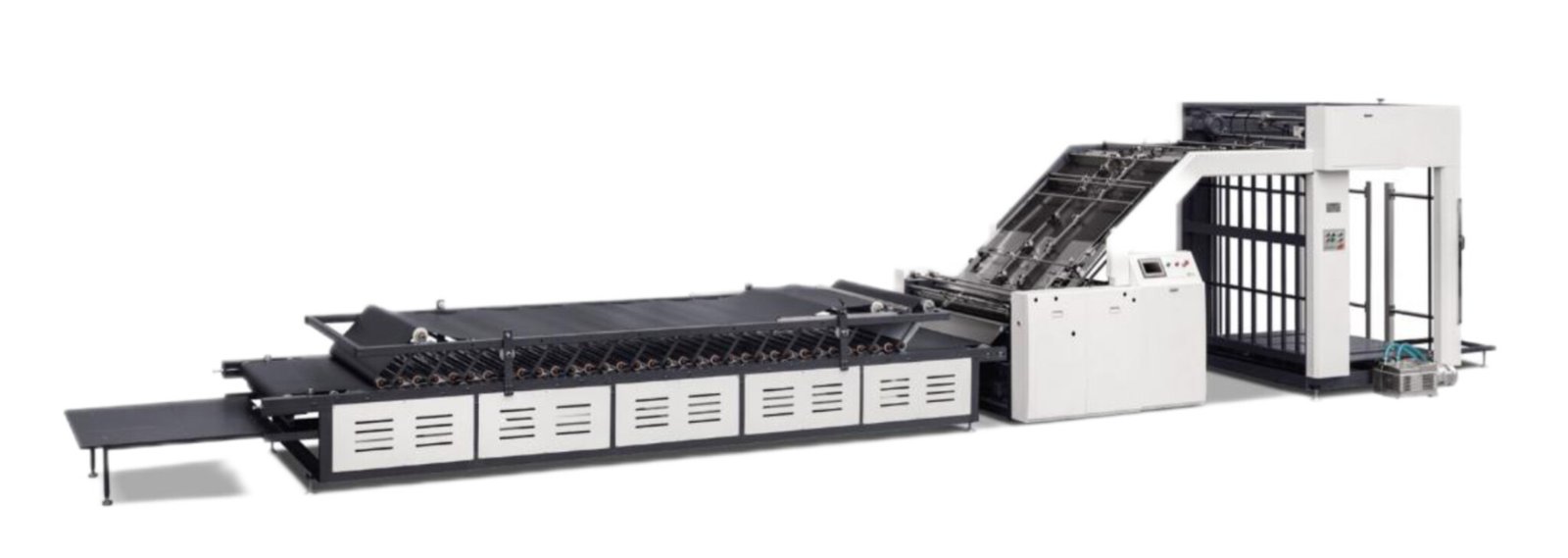

High Speed 3Ply Flute Laminator Machine

Learn more

Film Lamination Machine

Learn more

5 Ply Flute Laminator Machine

Learn more

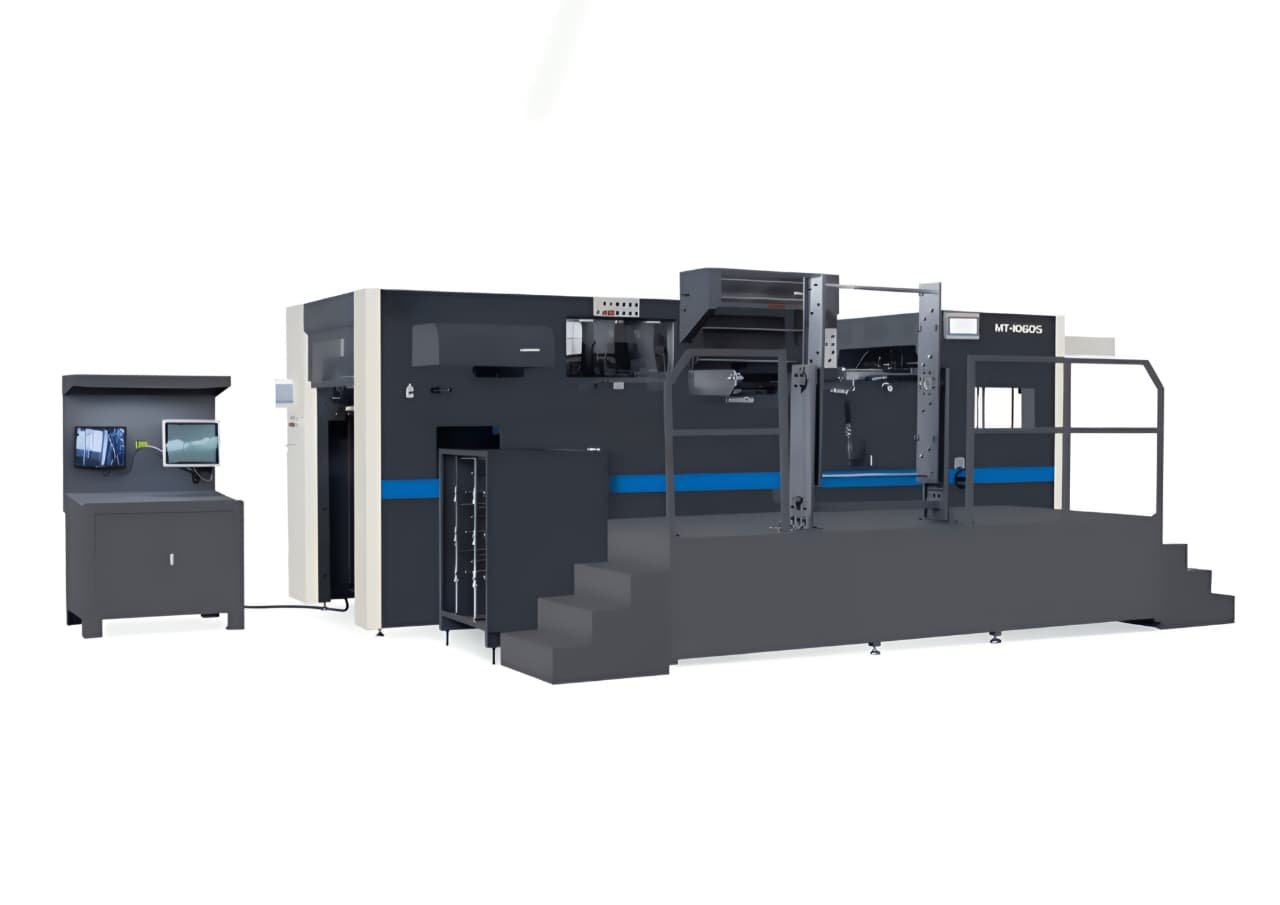

MT 1080 Automatic Die Cutting Machine With Foiling.

Learn more

Automatic Flute Laminator Machine

Learn moreGet in touch

You will find yourself working in a true partnership that results in an incredible experience, and an end product that is the best.

Call us on

+91-8630165313

Email us

kpmachineryandservices@gmail.com